Open the rear axle,unbolt the center pin,pull the center pin out push the axles in to free up the C clips, pull the axles out. Remove the seals use a bearing puller on the axle bearings. If you know for sure that two front wheel bearings are going its best to do them asap. Nick, the wheel bearings on your Chevy truck are not serviceable.

They are part of the hub assembly. I am sure someone, somewhere does sale the bearing alone. But most parts houses include it as part of the hub kit. Loosen the lug nuts and lift the wheel using a jack. Unscrew the lug nuts and remove the wheel.

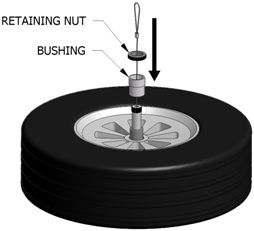

Learn how to replace a wheel bearing hub assembly. Wheel Bearing Replacement. Press the center of the wheel bearing out first to access the snap ring.

Flip the knuckle assemble over and remove the snap ring. Use a large chisel to crack the inner race at the slice. Insert Inner Bearing and Seal: Turn the hub over so that the front side with the wheel studs faces down on the table.

Place the inner bearing in the hub and install the seal on top. Tap the seal in a circular motion until it sits flush. Next, apply a thin layer of grease to the spindle. The video is meant for entertainment purposes only. If the wheel bearings are housed inside your disc brake.

Step 4: Rub bearing grease into the casing. Using your Channelocks or adjustable wrench, remove the nut from the. Plug in the ABS lines or reattach them to the bearing , if applicable. Replace the tire and lug nuts, and tighten the lug nuts as tight as you can get them. Lower the vehicle and tighten the lug nuts in an alternate fashion with the torque wrench and socket at the correct wheel nut specifications torque setting.

On your car, the bearing supports the wheel and rides on the axle shaft. It fits into the hollow section at the center of the wheel , and is held in place by the lug bolts which attach the wheel to the car. The wheel bearing is pressed into the back of the wheel , before being bolted into place. Crank down on the threaded shaft of the bearing removal tool to extract the bearing. Apply high-temp grease lightly to the new bearing.

Convert the wheel bearing removal tool to the replacement mode and install the bearing. Reinstall the bearing race retainers by replacing the bolts in the housing. I used this large socket in lieu of a traditional bearing press as it was the perfect size to get the bearing seated in the.

The wheel hub bearings hold the wheels on to the axle and drive assembly, and allow them to spin properly. Most wheel hub bearings last for about 150miles, at which time they will need to be replaced. In addition to using grease for packing headset bearings , I also like to use a little grease to help ease the friction between bearings and metal core wheels during installation. Once packe insert the inner bearing and seal, followed by the outer bearing and seal.

Then simply put the wheel back on and jack the trailer back down.

Be sure to grease the spindle along the way. Toyota 4xhow to replace front wheel unit bearings. Push the assembly back on the spindle. Using a 35MM socket remove the large hub nut.

Pull the drum or rotor assembly straight off the spindle. Do not let the inner bearing or seal drag on the spindle threads. Once the first bearing is out, the spacer tube will slide out making it dead easy to flip the wheel over and knock the other bearing out. With both bearings out, give the hub and bearing spacer tube a really good clean, getting rid of any old grease and muck that’s accumulated over the years.

Insert the inner bearing into the hub with the small end first and spread a film of grease around the sealing end (the flat, smooth side). With the flat, smooth side of the seal toward you, place the seal in the hub opening, and use the pipe or socket to move it into the hub gently and evenly. The new seal should end up flush with the outside of the hub or slightly inside it. How to Install an Axle on a Trailer. Tighten the brake line to the trailer brake lines using the brake line wrench.

When to replace wheel bearings. Most car manufacturers recommend wheel bearing cleaning, re-packing with grease, and having them inspected every 30miles. This is normally done with a brake service. Once the cap has been removed it will expose the outer bearing, retainer, nut or castle nut, and cotter pin. There will be grease present which is used to lubricate the bearings.

Use a shop towel to clean the cotter pin area free from grease. Next, use a pair of dikes to remove the cotter pin from the spindle. Now pop off the dust cap with a chisel and a light hammer tap. Then, use pliers to straighten the cotter pin. Your inner wheel bearings lay in the center hole of the drum or disc.

At this time, you have to decide whether you’re going to remove the inner bearings to check and pack them. Generally speaking, if the outer bearings look okay, the inner ones are okay, too. Replacing wheel bearings on a trailer is not as complicated as you might think. Here we will show you step by step how to replace the wheel bearings on your boat trailer. Loosen wheel nuts slightly to just crack the tension off them, then jack the trailer up just enough to get the wheel off the ground.

On a car, a wheel bearing rides on a metal axle shaft and fits tightly inside the hub, which is a hollow chunk of metal at the center of the wheel. The hub holds the lug bolts that you use to bolt the tire onto the wheel. Use a long punch (should have a good edge) Remove any Circlips or retainers. Insert the punch into the wheel and catch the edge of the bearing on the other side.

The bearing and seal will eventually be pushed out of the wheel hub. Reuse of the old nut could potentially cause the nut to loosen during vehicle operation. Do Clean the Axle Shaft before Installation. Clean and inspect the axle shaft prior to installing a new hub assembly.

Use a fine file, wire brush, emery cloth or honing stone as appropriate to remove any debris, nicks or burrs. Inspect the new seal to ensure that it’s not flawed. Drench the inner bearing with clean lubricant, the type being used in the wheel end.

Wipe the seal bore with a clean towel.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.