Has both a grinding and honing wheel. Stuart Batty Angle Gauge One. Find great deals on eBay for wheel jig and wheel truing stand. With the hub and rim secured and aligned to hold radial, lateral, and wheel dish positioning, the spokes can be installed with greater ease and accuracy.

Each jig will hold wheels, enough to do one car. Simple plans for a jig to make spoked horse-drawn wagon wheels. Designed for inch wheels but can be adapted for any size. Save jig grinding wheels to get e-mail alerts and updates on your eBay.

Wheel Maker Jig Woodworking Plan. Basically, anyone who is interested in building with wood can learn it successfully with the help of free woodworking plans which are found on the net.

A wide variety of wheel jig options are available to you, such as free samples, paid samples. There are wheel jig suppliers, mainly located in Asia. The top supplying country is China (Mainland), which supply 1 of wheel jig respectively.

The world’s most popular wheel truing stand and the standard of the bicycle industry for years is now, more than ever, the stand to choose for daily shop use.

The jig was designed in SketchUp and laser cut out. Roller skate wheels are roughly cylindrical, so the two dimensions that affect a wheels behavior are the width of the wheel across the contact surface and the height (diameter) of the wheel across the hub. A threaded insert and thumbscrew at the opposite end of the hole advances the tip towards the wheel. Another insert and thumbscrew on the top of the block locks the tip in place.

A section of aluminum angle on the bottom edge of the block registers the jig against the tool rest. Building a jig for wheel assembly. This video is unavailable.

It consists of a hardened steel workholder which holds the wheel and acts as the guide for filing the rim. Included is a very quick and easy way to paint and weather wheels. Setting up the Oneway Wolverine Vari-Grind Jig System is not complicate but attention to details is essential. When duplicating an existing wheel , the old wheel is clamped over the new wheel blank and the spokes are simply scribed using the existing pattern.

One of the trickiest parts of getting a touring body prepped is getting the wheel wells cut out, and now Schumacher is helping to simplify the process. To start, here are some pictures of my truing jig , which. Even if you can’t true the wheel , if you at least have the wrench, someone might be able to help you on. Preciray professional wheel building jig - originally supplied to main dealers as part of their workshop setup.

Refine your search for wheel jigs. Welding’s Most Wanted is the bridge that connects its users to the welding industry through a powerful, personalized platform to share and market their individual craftsmanship. Tormek Advanced Water Trough For T7. Easily drill and install spokes evenly. Start with a copy of the plan that is sold separately, select the wood of your choice.

Updated daily, there is a lot to offer. Sharpening with a Grinding Jig and Buffers. Your turning tool is the work, and the fixture guides it using the grinding wheel (the cutting tool) as reference. Lastly the wheel jig platform is mounted to the upper and lower mount assembly using wing nuts. Using THREE points of contact to keep the tire roun the GRYPR is the ultimate in precision.

Every bike has a front and rear wheel jig built into it. Pro Body Jig Video Transcript. It would be nice to have something that could be desk mounted with pins to make sure its centered etc.

Rock the Wolverine Vari-Grind Jig left and right until a smooth curve replaces the harder angle of the heel. Controlling the Wolverine Vari-Grind Jig. While using the Wolverine Vari-Grind Jig , I stand to the side of the grinding wheel and hold the Wolverine Vari-Grind Jig with both hands. If you have a jig -grinding problem, describe the details to us: Work piece material Work piece hardness Type of finish required Specific problem Our grinding wheel specialist will provide recommendations for wheel type, abrasive, grit size, speed and feed rate.

Their are a number of sites including You tube videos. I do not use loctite but key the axle and wheel hub at 90° on each end of the axle. Line up your jig so that the pilot bit on your hole saw lines up directly with the hole in the center of. Even with the routing jig to align the parts, accurate hole drilling is a must if you want parts to actually fit together.

Here is the assembled wheel , on the routing jig. I had to make the wheel hub in three pieces so that the rim would lie in plane with the hub on the jig. The wheel is great for indexing your column when mounted in a jig. For those of you who do not know this blade, it is an. A handy device for quickly and accurately setting loco driving wheels at degrees to each other, where the axles do not have squared ends, but are tapered for press-fit wheels.

NOTE The axles must have centred ends, and wheels must have identical crankpins fitted. Wolverine Grinding Jig to work best, your grinder and your grinding jig should both be mounted on a board or a bench so that they cannot move in relation to each other. The base should be mounted directly centered under your grinding wheel.

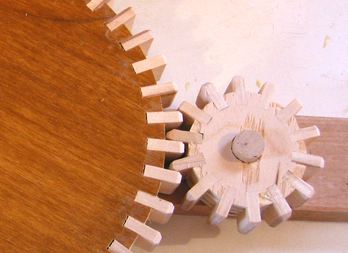

Slide the vee-arm into the base to ensure that the centre of the pocket lines up with the centre of your. Click the add comment button above to comment. Homemade model making jig intended to facilitate the process of fabricating spoked model wheels. Constructed from plywood and hardware.

Jig is slotted to accommodate different wheel diameters. Jig , sinker, and spinner bait starter kits, with everything you need to start making lures. In addition to the desired bevel angle, corrections are required to account for wheel diameter, chisel thickness and chisel taper angle.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.